THE ONLY SUSTAINABLE WAY FORWARD IS TOGETHER

#PROJECTZERO

Thinking ‘sustainability first'

We commit to reducing our impact on the planet by developing sustainable products, solutions, and production methods and studying the impact of the 3D Printing industry.

Reduce

We develop products, solutions, and production methods that enable the future of sustainable manufacturing.

As a part of our mission to enable sustainable Additive manufacturing, we produce a range of sustainable materials including:

- 2 Recycled Materials: Made from post-consumer or post-industrial plastic waste

- 7 Bio-Based Materials: Derived from renewable resources such as plants, crops, or algae

- 30+ Recyclable Materials: Can be collected and processed to create new products after their initial use

Switching to 90-100% post-industrial recycled material for our spools and FSC® certified cardboard as well as redesigning packaging in our Ultrafuse® filaments portfolio has reduced the impact of consumer packaging. For example, for Ultrasint® rPET, optimised packaging has a 12% reduction on CO2.

Lead

We study the impact of 3D printing to enrich the discourse of sustainability across the industry.

A lifecycle assessment (LCA) calculates the environmental impacts that are associated with every step of the production of a product. Forward AM has completed 12 LCAs as a part of our commitment to understanding the impact of our materials as a part of the 3D printing process.

To support our customers in their sustainability goals we offer a CO2 calculation service measuring the footprint of part production for a given material and technology.

Empower

We create positive change at the grass-roots, knowing that every contribution adds up to make a meaningful difference.

Our Carbon Compensation program enables customers to offset the environmental impact of their material usage by working with accredited organizations to finance long-term carbon capture projects.

The ISO 14001 certification drives companies to consistently maintain high environmental performance standards by reducing waste, energy usage, and greenhouse gas emissions. This certification creates a solid framework to guide BASF Forward AM through our multiple sustainability initiatives.

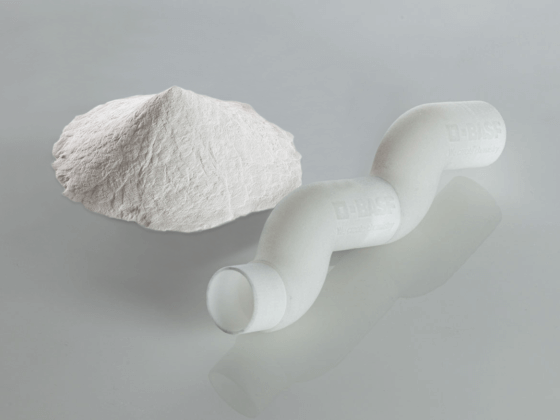

Forward AM provides recycling and take back program for its Ultrasint® PA11 and Ultrasint® TPU lines. Customers can return unused material and printed parts to be transformed back into fresh material.

Read more about Forward AM’s sustainability contribution

03/22/2022

Discover how Sustainable our Filament Business Line really Is

We not only have sustainable Ultrafuse® materials but also support other initiatives to…

02/10/2022

For a more Sustainable Tomorrow – What Additive Manufacturing Brings to the Table

Circular economy, biodegradability, recyclability – these are just some of the terms…

02/10/2022

Creating chemistry for a sustainable future

Sustainability is the biggest challenge of our time – and BASF has set itself ambitious…

02/10/2022

Building a Sustainable Future – Forward AM Initiatives

Additive Manufacturing holds tremendous potential to advance sustainability in comparison…

11/03/2023

Reducing Operational Downtime by Utilizing Ultrafuse® PLA Tough Designed for High-Speed 3D Printing

Developing innovative materials and processes to provide workable solutions to help our…

10/16/2023

Update: Forward AM’s Filament Materials Deliver on Both Performance and Sustainability

We not only have sustainable Ultrafuse® materials but also support other initiatives to…

10/13/2023

Company Voices on Sustainability Vol. 3

The Innovative Development of Sustainable Products: Shaping the Future of Recycled Spools…

08/24/2023

Company Voices on Sustainability Vol. 2

Studying the Impact of the 3D Printing Industry: Ultrasim® 3D sustainability analysis…

05/16/2023

Company Voices on Sustainability Vol. 1

Educating and Encouraging Our Team to Make Responsible Choices: Cycling to Work with Tim…

09/23/2022

3D printing and spare parts: Discussion on the environmental benefits

Sylvain Haasser (Head of Alternative Solutions at Groupe SEB), Pierre-Jacques Lyon…

04/22/2022

How Ultrasint® TPU Enables a Recycling Stream

Discover how Ultrasint® TPU can be sustainable within the production process and beyond.